Details

Specification

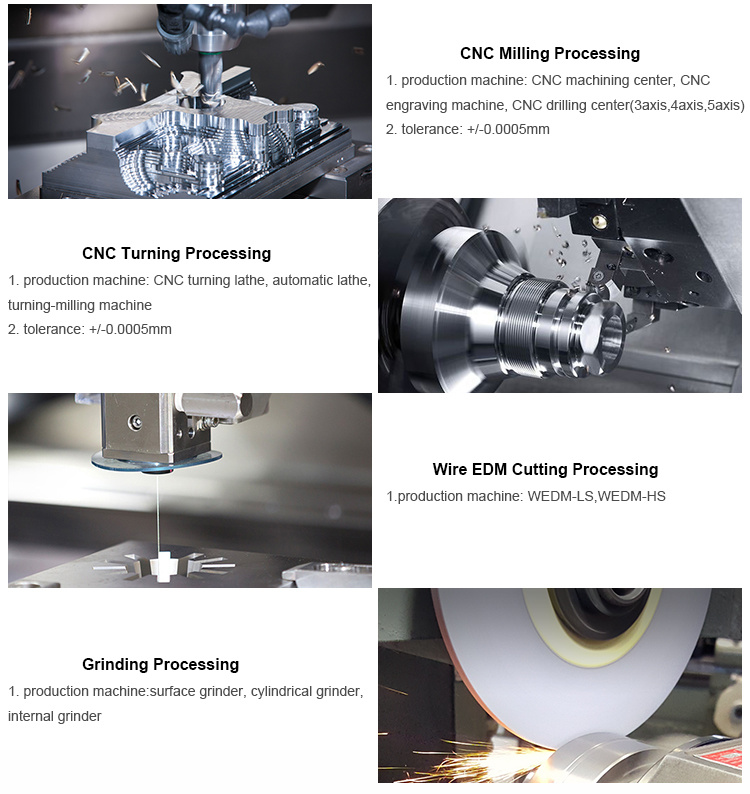

| Item name | CNC machining |

| Tolerance | minimum tolerance 0.005mm |

| Material | Stainless Steel: SS201,SS301,SS303, SS304, SS316, SS416 etc. |

| Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |

| Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |

| Copper: C11000,C12000,C12000, C36000 etc. | |

| Plastic: ABS, PC, PE, POM, Delrin, Nylon,PP, Peek etc. | |

| Other: Titanium,Titanium alloy etc.We handle many other type of materials. Please contact us if your required material is not listed above. | |

| Surface Treatment | Stainless Steel:Polishing, Passivating, Sandblasting, Laser engraving,Oxide black,Electrophoresis black |

| Steel: Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, Heat treatment. | |

| Aluminum:Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing. | |

| Brass: Nickel plating,chrome plating,Electrophoresis black,Oxide black,Powder coated. | |

| Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser engraving. | |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Testing Machine | CMM,Digital Height Gauge, caliper, Coordinate measuring machine, projecter machine, roughness tester, hardness tester and so on |

| MOQ | 1 piece |

| Delivery time | 10-15 days after placed order |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

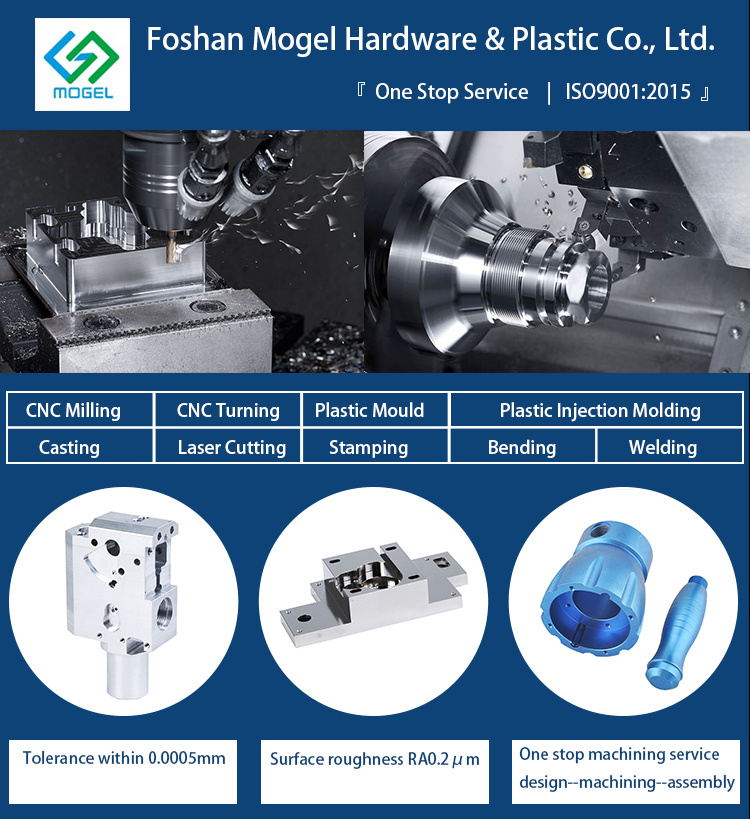

Company Profile

Foshan Mogel Hardware & Plastic Co., Ltd. was founded initially as a Plastic injection molding and tooling fabrication plant from2006, afterwards growing quickly and set up Mogel Industry Limited in HK, we have several divisions,focusing on turnkey solutions inclusive of the CNC machining, Punching, Stamping and assembly , Based on our extensive experience and deep understanding of mechanical and plastic components manufacturing,and now become a growing innovative mechanical , plastic components engineering design and manufacturing company.

Mogel group is proud to offer a comprehensive suite of compact and cost-effective products to our partners, monitoring and maintenance operations with the utmost in quality. Our factory are engaged in mechanical and plastic components manufacturing over 10 years with our goal to leverage on our synergetic capability to add value to our customer and grow the business together.

Strict inspection we do during operation

1. Experienced QC testers to check the products dimension, surface and performance according to drawings specification.

2. Experienced IQC to check the dimensions and surface of the incoming material.

3. Experienced PQC to inspect full-course during the processing.

4. Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

Quality sample will be provided for your testing before production according to ISO 9001: 2008.

We are pleased to service you with excellent quality, reasonable cost and grow withyou together.

Our Advantages

1.Small details make big difference.All the parts from our company have no sharp edge. All dimensions are controlled

according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and

professional inspectors.

4. Each size of product must be tested one by one after completing production.

5.We have many years of export experience,exports to the US,Europe, Southeast Asia and other countries and regions.

Our Service

Secondary operations:

anodizing,painting,polishing, powder coating, sand blasting,Passivating,Laser engraving Oxide black,Electrophoretic black plating,and heat treatment.

Details Images

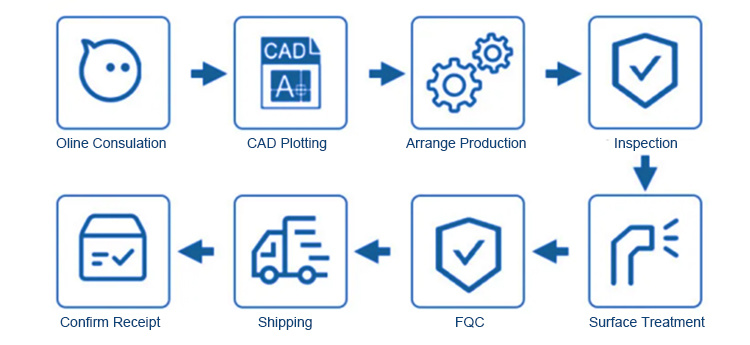

Production Process

-

Keywords:

- Anodized machining parts 008

Inquiry