custom plastic injection molding service

Features

Details

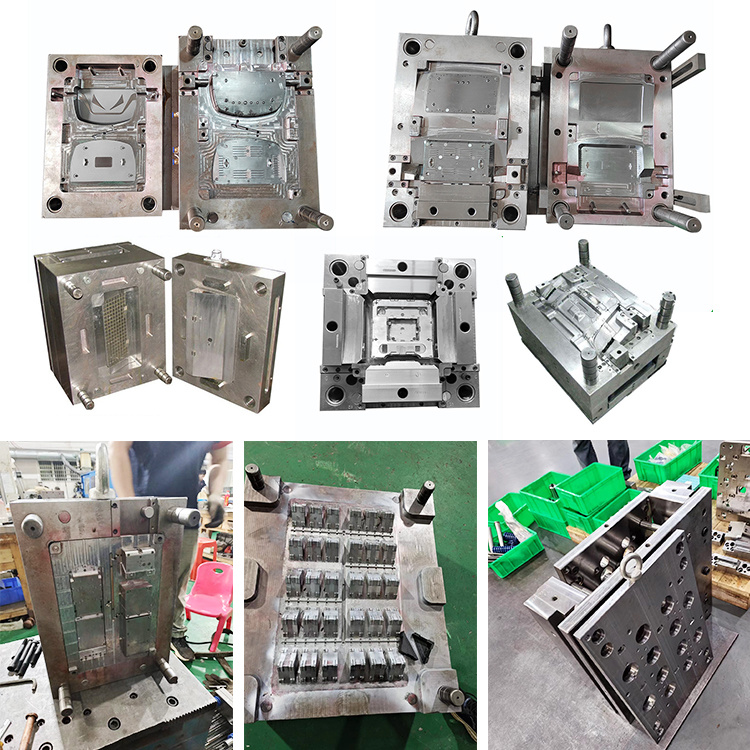

| Product range | Producr design,mold design, mold making and produce plastic parts |

| Processing Craft | Mold fabrication, Injection etc; |

| Material | ABS, PC, PP, , POM(Acetal/Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), PMMA(Acrylic), SAN/AS, ASA, PVC, UPVC,TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE(Teflon), GPPS, PPS, PPO, PES, CA, etc. |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Electroplating,Painting,Slik print,Rubber Painting etc |

| Color | RAL/PANTONE color |

| Mold Standard | DME,LKM,FUTA,HASCO etc. |

| Mold Material | S136H, 718H, NAK80, P20, H13, etc. |

| Tolerance | 0.01~0.1mm |

| Mold Life-cycle | 100,000-500,000 shots. |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC,FQC,QA |

| Application | All kinds of plastic injection parts being used in a variety of industrial application |

Our Service

Company Profile

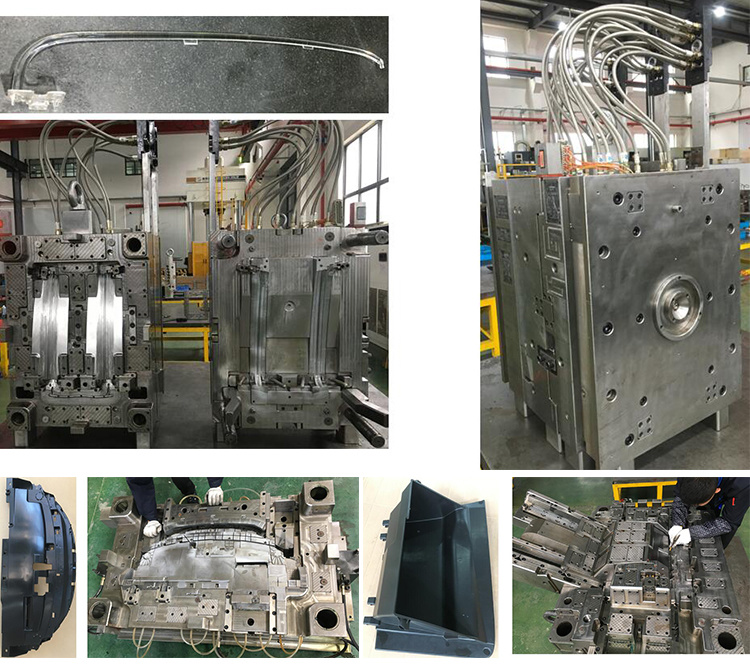

Our company has In-house tooling shop- fully equipped tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

This workshop is equipped with CNC milling machine, CNC lathe, electric spark, wire cutting, milling machine, grinding machine, drilling machine and other die special equipment.We mainly produce plastic injection mold, we have 20 years experience in mold making, we need according to customer's drawings or samples to provide clients with mold, can also be customized personalized service for you, such as product appearance texture, smooth surface, LoGo, words, etc.

We have 60 ton - 1500 ton injection molding machines 106 sets,We can produce parts from 0.01pound to 13 pound

We have three coordinate dimensional testing equipment, product hardness testing equipment, plastic products mechanical properties testing equipment, aluminum die-castinga products scanning equipment and mechanical properties testing equipment.

Quality control

1. Experienced QC testers to check the products dimension, surface and performance according to drawings specification.

2. Experienced IQC to check the dimensions and surface of the incoming material.

3. Experienced PQC to inspect full-course during the processing.

4. Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

We are pleased to service you with excellent quality, reasonable cost and grow withyou together.

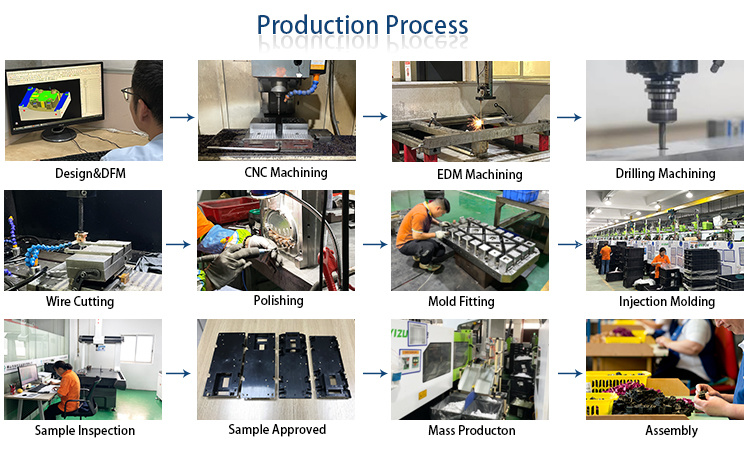

Once the mould making is finished, we’ll make several pieces of pre-production samples for test, if the dimensions are correct,then we will send the samples to customers for final confirmation. If the test failed, we will modify the mould or adjust the molding parameter to make new samples, and test it again. Once the samples are approval by customers, we will purchase the raw material and making quality inspection. Then mixing material, molding and trimming, we will make many times of inspection during the production. Finally we will arrange the assembly and packing. After whole order is ready, we will send the packing list to customer to arrange the shipment.

FAQ

Q1.How to have my components quoted ?

A1: Please contact us via TradeManager or Email and send us your drawings inclusive of 2D and 3D (.STEP or .IGE file) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit competitive quotation to you.

Q2.What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 40*45 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15 days normally.

Q3.Can I have prototypes for testing before tooling ?

A3: Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q4.How to ship the samples and production order ?

A4: We will normally ship samples via DHL, UPS or FedEX via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air

Q5.How to ensure the quality of parts?

A5: Firstly, our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production order.

-

Keywords:

- Anodized machining parts 047

Inquiry